اترك رسالة

Induction Heating Systems MillerWelds

Induction heating is easy to set up, offers a fast timetotemperature, and delivers exceptional heating efficiency, accuracy, and uniformity in part temperature In addition, induction offers safety benefits compared to

PRINCIPLES OF HIGH FREQUENCY INDUCTION TUBE

Induction welding is a form of Electrical Resistance Welding (ERW) in which the large rotary trans former common in low frequency ERW is replaced by a “virtual transformer”

(PDF) Inductionheated ballmilling: a promising asset for

While ballmilling is becoming one of the common tools used by synthetic chemists, an increasing number of studies highlight that it is possible to further expand

How Does Induction Heating Work in Welding? YouTube

This introduction to induction heating in welding applications will explain how it works and what it is To learn more about Miller induction heating systems

Tube Welding and Cutting Consumables & Induction Heating Coil

Inductotherm offers an extensive range of impedors to satisfy a very diverse range of tube and pipe welding applications Whether your mill produces small diameter/ thin wall

Induction Solutions: Tube plants SMS Elotherm

Induction welding, annealing and special technology for tubes Continuous induction strip heating Induction kinetics CUSTOMIZED SYSTEMATIC SOLUTIONS Elotherm’s

Welding With Induction Heating Improves Consistency

It offers a fast timetotemperature, provides great flexibility for a variety of applications and materials, and is a safer alternative compared to other heating methods In most welding applications,

Inductionheated ballmilling: a promising asset for

The purpose of this manuscript is to perform a proofofconcept study, to show how induction provides an attractive alternative for heating reaction media during

Inductionheated ballmilling: a promising asset for

Hence, developing setups enabling to combine heating and milling is an important target, which has been looked into in both academic and industrial laboratories Here, we report a new approach for

Induction tube welding TRUMPF

Induction tube welding Tubes for holding different types of contents in the cosmetics, medical and food industries usually have a bidirectional coatedaluminum barrier to

Improvement of the joint quality in the highfrequency induction

Highfrequency induction welding (HFIW) is among the most commonly used methods for producing roll formed pipes In this paper, weld quality is evaluated through examining the weld properties, in order to obtain the effect of edge preparation on improvement of weld quality Temperature distribution in the weld zone is studied through

Induction Tube Welding Sanket Power

All our induction welding system have rugged virtually shortcircuit proof, considerably boosting reliability and uptime You also get maximumoutput as of auto tune electronic load matching This secures full power output across a wide range of tube sizes (OD 10mm150 mm), ensuring maximumwelding speed for each size

Induction Heating for the Tube & Pipe Industry

UltraFlex has provided many manufacturers in the Tube and Pipe industry with induction heating solutions Induction heating provides quick, concentrated heat on focused areas which increases productivity,

Thermatool Corp High Frequency Induction Welding

High Frequency Induction Welding, Annealing, and Heating Systems Thermatool Corp, an Inductotherm Group Company, is the worldwide leader in High Frequency SolidState Induction Welding for tube and pipe applications From API to spirally wound fin tube to engineered structural sections, Thermatool’s innovations consistently push the limits

High Power High Frequency Welders Thermatool Corporation

With power ranging from 1000 2000 kW, Thermatool High Power High Frequency Welders are capable of welding from 150 400 kHz with fixed or variable frequency These welders perform in the most demanding applications Thermatool High Power HF Welders are available with the innovative 221 coil or the patented QuadContact™ weld tooling for

What is Induction Welding? Welding of Welders

Automotive Industry: Induction welding is extensively used in the automotive industry for joining components such as exhaust systems, fuel tanks, and engine parts It offers fast and reliable joining, ensuring strong and leakfree connections Aerospace and Aviation Sector: Induction welding finds applications in the aerospace

Welding With Induction Heating Improves Consistency and

Pipe fabrication and welding commonly use induction heat treatment But many contractors don’t realize induction can deliver benefits when welding flat plate, moving parts and other part geometries The Miller® ProHeat™ 35 Induction Heating System is available with numerous air and liquidcooled options, depending on the job

Research on Simulation and Optimization of Traveling Induction Heating

To observe the evolution mechanism of physical fields in the welding deformation rectification process by a traveling induction heating, research on simulation models of welding—induction heating continuous process were carried out Highstrength steel plates were selected for welding deformation experiment and induction heating

Mounting and Dismounting of Rolling Bearings Schaeffler Group

TI No WL 809 Aluminium Heating Ring for Cylindrical Roller Bearing Inner Rings TI No WL 8014 Mounting and Dismounting of Spherical Roller Bearings with Tapered Bore TI No WL 8038 Mounting of Selfaligning Ball Bearings on Adapter Sleeves TI No WL 8046 FAG Hand Pump Sets TI No WL 8047 FAG Induction Heating Devices

Induction Heating SpringerLink

Definition Induction heating is the process of heating a material through the generation of eddy current An external applied alternating magnetic field is applied, and heat is generated from the resistance to the eddy current (ie, Joule heating) Eddy current is the main heat source; however, heat may also be generated in magnetic materials

Coil & impeder position for induction welding

The coil ID should be such that there is sufficient clearance with the welded tube to avoid electrical<br /> flashovers or coil damage due to broken coil end welds For tubing from 25mm to 250mm,

What is Induction? Inductotherm Corp

The precise heating control available with induction is unmatched Further, using the same heating fundamentals as vacuum crucible heating applications, induction heating can be carried under atmosphere for

Inductive Heating Material Challenge Himmelwerk

Induction heating is a reliable and efficient method for heating a wide variety of materials In this process, heat is generated by the current induced in the component, on which a wide range of applications, such as heat treatment, brazing or melting, are based Depending on the process, parameters such as the choice of frequency or the

Induction Heating for aluminum and copper Forum for

260 cmitra said: Both copper and Aluminium have high electrical conductivity; that means induction heating will be less effective (compared to iron) if you increase the operating frequency, there will be less penetration due to skin effect If you decrease the frequency, you will need higher power

Induction Brazing Ambrell

Brazing steel dental tools To heat a steel tip and shank assembly to 1300°F (704°C) within 3 seconds for brazing with induction heating instead of torch brazing Brazing Copper J Tube into Fittings To braze a copper tube ( 3/8 in OD by 24 in long) into a 3/8 in fitting in less than 10 seconds

Analysis of induction heating system for high frequency welding

The aim of the work is the investigation of induction heating system used for longitudinal, high frequency pipe weldingCoupled electromagnetic and temperature field distribution has been studied

Comparing Methods for Welding Preheat Fabricating and

The Four Common Preheating Methods In welding preheat, the heat can be applied around the area of the weld joint or the entire part can be heated There are four common preheat methods: Open flame Operators mix fuel gas with oxygen in a torch with a large heating tip, typically called a rosebud, and apply flame directly to the part

Induction Heating an overview ScienceDirect Topics

Induction welding is a type of electromagnetic (EMA) welding, along with radiofrequency welding and microwave welding, which uses electromagnetic energy to heat materials The three methods differ in the frequencies used for heating: 01 kHz to 10 MHz for induction welding, 13 MHz to 100 MHz for radiofrequency welding, and 2 GHz to 10 GHz for

Induction Heating Calculation Tool Ultraflex Power Technologies

Ultraflex Power free induction heating calculator tool is a powerful and easytouse online tool that can help you calculate and optimize your induction heating process You enter your material properties, coil specifications, and heating requirements and get instant results on essential parameters such as power density, heating time, and

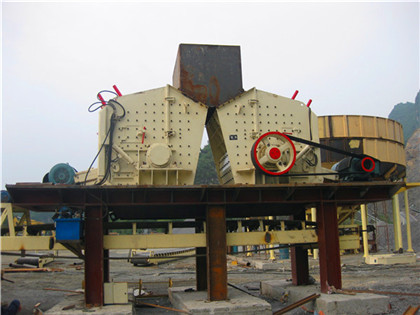

Forming & Welding & Sizing Section New Victor Tube Mills

The proper welding section setup and arrangement in relation to induction welding are important to ensure effective and efficient welding operation Squeeze roll diameter, seam guide, welding coil, impeder and impeder cooling affects the rapid heating of the strip edge to be welded, specifically critical for small tube induction welding below diameter 127