اترك رسالة

Hammer Mills ERS Engineered Recycling Systems

Our hammer mills are the answer to the challenge of selectively shredding hard and brittle materials Hammer mills also take the pelletization of rubbery materials as preparation for downstream separation systems

Hammer mill shredder and scrap crushers STOKKERMILL

Hammer mill scrap shredders and crushers of HM series are designed for the volume reduction of heterogeneous scrap with the aim of dividing and recovering the ferrous and metallic fractions The hammer mills of the

Industrial Shredder Hammer Mill Shredder And

Hammer Mill Shredder Our hammer mill shredders are designed to be the most durable, efficient, reliable, and costeffective shredders in the industry Their robust design allows them to be employed as primary or secondary

Large Metal Hammer Mill Shredder Shredwell Recycling

Hammer mill shredder rotors is specially designed with less maintenance, it does not have to be replaced, just hard faced every couple of years The rotor powered by Siemens motor giving plenty of power for shredding

Metals Recycling Hammer Mills / Shredders

Hammer Mills & Shredders for Recycling Metals Schutte Hammermill offers a several equipment models for processing goals such as: bonded metal separation, volume

Hammer Mills Erdwich ZerkleinerungsSysteme GmbH

Efficient and safe operation PLC control with overload protection to protect the machine from damage in case of overload or from solid parts Experience our shredders at first hand Testing material under real

Hammer Mill Shredder Videos & Resources 3TEK

Take a 360° Tour of the Alpha 74002500E Shredding System VIEW NOW FEATURE VIDEOS PARTS & SERVICE VIDEOS SPEC SHEETS

Bonfiglioli Drake 16HP/16/12/10 Ing Bonfiglioli

Bonfiglioli SpA has garnered a global reputation for highquality recycling processing systems The compact, semimobile DRAKE Shredder is available in a 10, 12, 16 or 16 doublemotor hammer design with processing capacities of up to 13, 16, 28 and 44 tons/hour respectively The DRAKE Shredders process loose light iron,

Single Shaft Shredder Two Shaft Shredder Four Shaft

Waste Shredders Our waste shredders are built to last,with a SIEMENS motor and Schneider components utilized our range of waste shredders can cope with whatever material you wish to shredAdd other parts to make it

Hammer Mills equipment for Waste and Recycling

Bonfiglioli Drake Model 16HP/16/12/10 Hammer Mill Shredder System ENERPAT Hammer Mill designed for shredding scrap metals like: car engine,car wheels,motors,steel scrap,aluminum scrap such scrap metals,shredding and separating steel,aluminum,nonmetal materialsCapacity from 5 tons/h to 30 tons/h

Hammer Mill, Hammer Mill manufacturer & Supplier from Pune

Shredding scrap automobiles (see automotive shredder residue) Shredding yard and garden waste for composting Crushing large rocks In waste management Your onestop destination for hammer mill system needs Our expert team is ready to get you all the answers! Contact Us Now

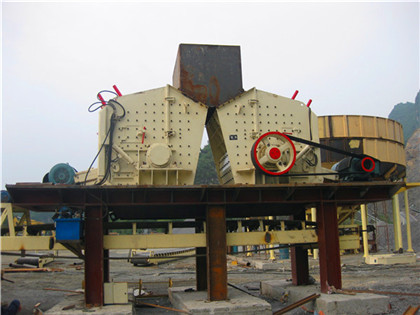

Hammer Mill

Hammer Mill ENERPAT Hammer Mill designed for shredding scrap metals like: car engine,car wheels,motors,steel scrap,aluminum scrap such scrap metals,shredding and separating steel,aluminum,nonmetal materialsCapacity from 5 tons/h to 30 tons/h Adopting UK technology,100% high quality with CE,ISO certification

Intro to Size Reduction Schutte Hammermill

How Does a Hammer Mill Work? Crush, grind, pulverize, shredsize reduction is amazing! There are many terms that fall under this umbrella: crush, grind, pulverize, shred, delump, defiberize, just to name a few Likewise, there is a whole host of machinery styles that accomplish these goals: hammer mills,

Metal Recycling Plant scrap metal recycle system

Shredwell scrap metal recycling plant is designed for shredding and recycling different metal scrap Waste metal shredding system is ready for sale Skip to content Call Us: +86 and a heavyduty VS series vertical shredder or HM series hammer mill for further processing

Fine Shredding of Municipal Solid Waste

Both types of hammer design (swinging or rigid) have been used with the vertical hammermill A typical vertical shaft hammer mill is shown in Figure 2 The inclu sion of fine shredding capability in the overall system, to reduce the product size distribution, will increase capital costs, but in the long run,

World's biggest mobile hammer mill shredder takes entire cars

First the system is run up to 400 kW without load When scrap reaches the hammer mill via the conveyor belt, the load factor is about 82% The shredder is capable of shredding 20 to 40 metric tons of scrap metal per hour

Efficient & Economical Modular Shredders WENDT CORPORATION

WENDT ‘s 45+ years of experience allows us to customize our shredders to achieve maximum productivity in any footprint Our line of replacement shredders allows us to upgrade old, outdated shredders with stateoftheart technology and modular features that offer minimal downtime Common sizes such as 80 x 104 and 98 x 104

Shredders, Granulators, And Hammer Mill Made In China Enerpat

ENERPAT Hammer Mill designed for shredding scrap metals like: car engine,car wheels,motors,steel scrap,aluminum scrap such scrap metals,shredding and separating steel,aluminum,nonmetal materialsCapacity from 5 tons/h to 30 tons/h Adopting UK technology,100% high quality with CE,ISO certification

Horizontal Hammer mill Shredder, Price, Quotation

PS7080 hammermill shredder mostly shred metal cans, paint bucket, hard drive and thin materials FEATURES 1 PS7080 feeding opening size is 800mm 2 Crushing cavity width is 700mm, rotor's rotating diameter is

Hammer Mill Shredder Videos & Resources 3TEK

Take a 360° Tour of the Alpha 74002500E Shredding System VIEW NOW FEATURE VIDEOS PARTS & SERVICE VIDEOS SPEC SHEETS

Mechanical Volume Reduction SpringerLink

Mechanical reduction volume for solid waste generally requires a large mechanical structure to operate For example, in the shredding process, a hammer mill machine is usually used at the site A shredding plant is normally set up for two shifts per day with ample time to cater to the maximum load of wastes

Plastic Crusher & Plastic Granulator Archives Wiscon Envirotech

Plastic Granulator CL Series Preshredder PC Series Double Rotor Shredder TD Series Shreddercrusher Combined CT Series Special Hammer Mill for Lithium Battery Recycling Quad Shaft Shredder Q Series To view a complete list of plastic crusher and granulator, such as CS and CL series They fit all sizes of plastic waste

BIMIX: Hammer mill for biomass TIETJEN

Contact us Phone +49 4106 63 330 Fax +49 4106 81 444 EMail nal Prepare unpackaged commercial biowaste and agricultural waste for biogas production The waste is shredded and grinded using the BIMIX

Hammer Mill at Best Price from Manufacturers, Suppliers & Dealers

2 天之前Find here listing of hammer mill A hammer mill is a grinder used to break solid materials into smaller fragments by crushing or shredding This multipurpose mill is used in paper shredding, grain milling, scrap shredding, rock crushing, juice making, etc Main components of this system are feed hopper, crushing chamber

Large Metal Hammer Mill Shredder Shredwell Recycling

Hammer mill shredder rotors is specially designed with less maintenance, it does not have to be replaced, just hard faced every couple of years The rotor powered by Siemens motor giving plenty of power for shredding process Heavyduty wearresisting hammer and gear design extremely lengthen the life time and decrease the operation cost

Shredders for Plastics Recycling Schutte Hammermill

Shredders for Recycling Plastics Schutte Hammermill offers equipment ideal for reducing plastics for recycling, with end products ranging from small plastic granules to long striplike pieces All models are custom configured to suit the user's material and processing goals