اترك رسالة

Crushing Plant Design and Layout Considerations 911

There are three main steps in designing a good crushing plant: process design, equipment selection, and layout The first two are dictated by production requirements and design

Crushing and Screening Handbook AusIMM

Lokotrack primary mobile crushing plant to further processing stages They are able to follow the primary unit as it moves along the quarry face, replacing costly dump truck

Crushing plant

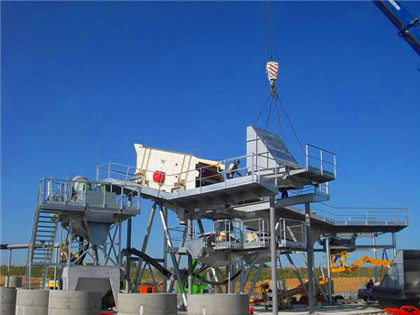

A Crushing plant is onestop crushing installation, which can be used for rock crushing, garbage crushing, building materials crushing and other similar operations Crushing plants may be either fixed or mobile A crushing plant has different stations (primary, secondary, tertiary,) where different crushing, selection and transport cycles are done in order to obtain different stone sizes or the required granulometry

Factors affecting the performance of crushing plant

PDF Crushing plants have been of great interest in reducing the particle size of ores milling operations need to consider

Crushing in Mineral Processing 911 Metallurgist

Crushers for large giant process plants >2,000 to 200,000 TPD using semiautogenous mills only require primary crushing and are selected as well as designed based on: Expected Throughput;

The Evolution of Crushing and Grinding: Changes in the

Crushing and grinding processes have undergone significant changes over the last 20 years These adjustments have focused on lowering costs and increasing

Summary of Gold Plants and Processes ScienceDirect

Crushing, milling: Large SAG operations with water cannon return; trommel oversize is returned directly to mill with water jet; retrofit pebble crushing is

Crushing Plant an overview ScienceDirect Topics

A crushing plant delivered ore to a wet grinding mill for further size reduction The size of crushed ore (F 80) was 40 mm and the SG 28 t/m 3 The work index of the ore was

Design and Evaluation of an Expert System in a

This document presents a proposal for designing an expert system in the Gabriela Mistral Division’s crushing plant belonging to Codelco (Chile) with the objective of maximizing stacked tonnage,

AMIT 135: Lesson 5 Crushing Mining Mill Operator

The purpose of the primary crusher is to reduce the ROM ore to a size amenable for feeding the secondary crusher or the SAG mill grinding circuit The ratio of reduction through a primary crusher can be up to about 8:1

Crushing Energy Efficiency North American Mining Magazine

If “the geological block model can be linked to the mine plan and ultimately a realtime model of the processing plant, which can then be imported to an advanced control system and used to set the control parameters and set points for the plant,” argued engeco in a recent report on energy consumption in mining, “the operation as a whole

Mineral Processing Operating Cost Estimate of Ore

In the case of the more modern continuoustreatment plants, East Geduld’s total milling cost in 1946 was 36d (60 cents), of which Cyaniding accounted for 195 cents The percentage cost

crushing, milling French translation Linguee

Many translated example sentences containing "crushing, milling" FrenchEnglish dictionary and search engine for French translations

An Integrated Mineral Processing Pilot Plant Practical Programme

PDF On Jan 1, 2007, EL Thyse and others published An Integrated Mineral Processing Pilot Plant Practical Programme Designed For Heavy Mineral Sands Beneficiation Find, read and cite all the

Limestone crushing and milling plant manufacturers germany

C&M Mining Machinery can provide complete sets limestone crushing and milling plant for sale such as jaw crusher, impact crusher, cone crusher, mobile crusher,LM Series Vertical Mill, MTW Series Trapezium Mill Raymond Mill ,Ball Mill and so onHourly output of 700800 tons of limestone crushing equipment, stone blasting down

Performance optimization of an industrial ball mill for SciELO

The energy consumption in the ball mill was found to be 65 kWh/t of ore with a targeted product size below 1 mm The BWI of the ores varied from 58 to 78 kWh/t to reduce the particle size below 100 μ m, but in real time, the energy consumption is very high compared with the reported value of 65 kWh/t

Summary of Gold Plants and Processes ScienceDirect

Crushing, milling: Improved fragmentation can also lead to higher shovel and haul truck productivity, reduced boulder handling/secondary blasting costs, and higher primary crusher use: 17: Alumbrera: Argentina: Crushing, milling: 152mm steel increased throughput for hard ore types compared with 127mm makeup ball: 17: Batu Hijau:

Crushing and sizing technology for all stages

Crushing, sizing, milling, breaking technology for every application Raw materials are so diverse Even within a single mine or quarry you could be dealing with an extreme range: hard to soft, dry to sticky Your crushing and sizing solutions need to be able to cope with whatever you throw at them reliably, and in good time

(PDF) Field monitoring and performance evaluation of crushing plant

Crushing plants are of great interest in reducing a particle size of rocks and ores as milling operations need to consider sustainable development Since the crushing plants operate under harsh conditions and involve very abrasive material, multiple factors can influence their performance

Size Reduction of Solids Crushing and Grinding

Abstract The unit operation of the size reduction or comminution of solids by crushers and mills is a very important industrial operation involving many aspects of powder technology It is estimated that mechanical size

Gold extraction QueensMineDesignWiki

Ore Classification The efficiency and recovery of chemical processes involved in gold extraction is exclusive to the mineralogy of the ore Gold may exist as free nuggets or particles in alluvial or elluvial deposits or as

Crushing in Mineral Processing 911 Metallurgist

To feed a rod and/or ball milling circuit, you need to crush as follow: Crushing Stage Crusher: Feed Size: Crushers for large giant process plants >2,000 to 200,000 TPD using semiautogenous

Sulphur Grinding Plant Crusher Mills, Cone Crusher, Jaw Crushers

sulphur crushing milling plants Solution for Mining Quarry Sulfur Lump Crusher,Sulfur Grinding Mill,Ore Beneficiation Plant India Elemental sulfur production was 105 million metric tons;

Simplified Flow Sheet of the Processing Plant Download

Download scientific diagram Simplified Flow Sheet of the Processing Plant from publication: Modelling and Simulation of the Santa Rita Mine Milling Circuit The Santa Rita Mine, located in the

Crushing Mineral Resources

Our crushing business, CSI Mining Services (CSI), is the market leading crushing and screening contractor, providing safe, efficient and low cost solutions Our crushing services business is dedicated to providing worldclass, tailored, buildownoperate crushing, screening and processing plants for some of the world’s largest and

AMIT 135: Lesson 6 Grinding Circuit Mining Mill Operator

Objectives At the end of this lesson students should be able to: Explain the grinding process Distinguish between crushing and grinding Compare and contrast different type of equipment and their components used for grinding Identify key variables for process control Design features of grinding equipment (SAG, BALL and ROD MILLS)

ADM to build new soybean processing plant World Grain

05112021 By Arvin Donley CHICAGO, ILLLINOIS, US — Archer Daniels Midland (ADM) on May 10 announced it will build North Dakota’s firstever dedicated soybean crushing plant and refinery to meet fastgrowing demand from food, feed, industrial and biofuel customers, including producers of renewable diesel Based in Spiritwood, North Dakota

Crushing and Mining Malitech Engineering

Crushing and Mining With an extensive history in the crushing and mining business, Malitech Engineering has left a footprint that makes it a useful partner in community mining developments that empowers communities and creates value for the South African economy as a whole Our crushing and mining business strategy can be summarised as follows;

Fully Automatic Chili Powder Production Machine

Our chili powder production machine is characterized by high automation, simple operation, low labor intensity, low power consumption and high output The chili powder milling machine has several processes, including crushing, screening, dust collection and other processes, to complete powder processing The processing process is divided into