اترك رسالة

Roll Crushers Williams Crusher

Some standard roll crushers include singleroll, doubleroll, and tripleroll crushers They can also be designed with smooth or corrugated surfaces on the rollers to provide different levels of crushing action How Roll

Rolls Crusher Eriez Global Leader in Separation Technologies

These smooth roll crushers will rapidly reduce coal, ore and hard rock from maximum feed size of 20mm to fine sand Rugged construction, easy to operate, each roll has its own

Roll Crushers ScienceDirect

A smooth surfaced roll crusher had a roll diameter of 910 mm Its suitability to crush an ore at 100 t/h was being examined Preliminary examination

Smooth Drum an overview ScienceDirect Topics

Smooth Drum Smooth drum rollers (Figure 57a) are probably the most traditional type of equipment used for compaction of soils and asphalt pavements (which are actually just

Longlasting roller crusher and sizer solutions I

Smooth operator Smooth roller operation is assured through greaselubricated roller bearings Additionally, the toothed wheels on the gear drive are immersed in oil along

GENTLE

Smooth roll crushers are particularly suitable for medium and fine grinding processes, demanding a strictly defined byproducts such as coke duff, coal, rock, fireclay,

Crushers Akshar International Pvt Ltd

We are the leading manufacturers and exporters in India selling and distributing a wide range of Crusher for glass grade material worldwide Our crushers are widely accepted across various industrial sectors like

Roll Crusher New or Used Roll Crusher for sale Australia

All Roll Crusher posted here are either used Roll Crusher or new Roll Crusher Browse more, so you can find Roll Crusher that satisfy your needs! Used DOUBLE DRUM ROLLS CRUHSER 670 x 800 SMOOTH FACE Unit is complete with 1200mm Dia Pulleys It has a new set of rollers that are 670mm Face and 800mm in Diameter

Roll crusher Henan Deya Machinery Co, Ltd

Roll crushers are arbitrarily divided into light and heavy duty crushers The diameters of the light duty crushers vary between 228 and 760 mm with face lengths between 250 and 460 mm The spring

Roll crusher working principle Henan Deya Machinery Co, Ltd

Figure 4 four roll crusher structure The machine itself is equipped with two sets of cutting devices for turning roll skins 5 When the smooth roll surface are worn or grooved or pitted, the rolls can be repaired directly by using the cutting devices without disassembling the rolls, and the cutting devices are mounted on the walking tool holder

Crushing Machines & Plants at Best Price in India

Concrete Waste Crushing Machine, 3 Phase 125 HP ₹ 2,50,000 Get Latest Price Capacity: 1000 kg to 1500 kg Per hour Power: 3 Phase 125hp Crushing chamber size: 800mm x 800mm x 700mm Main Base Crusher plate: 20mm Thick with Bolting Arrangement for Easy Replacemen Max Input size: 400mm x 200mm x 200mm

Roll Crushers ScienceDirect

A smooth surfaced roll crusher had a roll diameter of 910 mm Its suitability to crush an ore at 100 t/h was being examined Preliminary examination showed that the kinetic friction factor was 036 when the speed of revolution was 33 rpm The average diameter of particles fed to the crusher was 200 mm and the SG of the ore

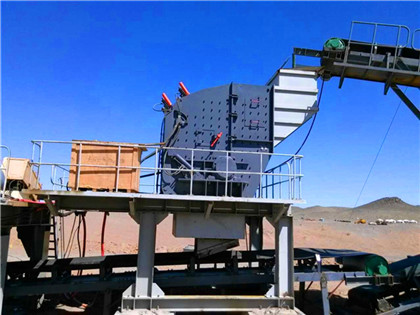

Types of Crushers: What You Need to Know Machinery Partner

There are lots of different kinds of crushers from jaw crushers to impactors and cone crushers Crushing is an versatile process and the kind of crusher you need depends on the 'stage' of crushing The three main stages of crushing are primary, secondary, and tertiary all of which have their own unique benefits

Double Roll Crusher DRC

The Double Roll Crusher’s hydraulic gap adjustment ensures consistently high performance with minimum disruption High throughput crushing & high efficiency DRS are capable of handling high throughputs, making them ideal for use in the mining industry Double Roll Crushers have reached production capacities up to 14,000 tph

Smooth Drum Compactors For Sale MachineryTrader

Smooth drum compactors come in a variety of weights and drum widths suited to almost any use Models range in weight from 15 tons (135 metric tons) to more than 28 tons (254 metric tons) to pack material into a dense foundation for streets, highways, airport runways, parking lots, and other projects

Eccentric Roll Crusher ERC®

We offer four Eccentric Roll Crusher ERC® types for various applications 1) Weights indicated do not include base frame, drive motor and tools Weights may vary depending on actual machine configuration 2) Motor rating range applicable for < 1,000m altitude Actual motor rating depending on the feed material characteristics, desired product

Download Free Drum Sound Effects Mixkit

Everything you need for your creative projects Millions of creative assets Unlimited downloads One low cost Download from our library of free Drum sound effects All 50 Drum sound effects are royalty free and ready to use in your next project

Compaction Equipment Rental Rollers, Rammers & More Coates

Coates solutions include a wide variety of compaction equipment and machinery for every soil compaction task PADFOOT ROLLER Heavy duty padfoot rollers utilise large weights and high impact force to compact cohesive clay and mixed soils Single drum padfoot rollers at Coates range from 3t to 16t machines with a drum width of 2130mm

Double Roll Crushers Moore Watson Ltd

HyproCrush ® Double Roll Crusher Series The HyproCrush DRC series is a British engineered product designed for high speed production of fine minerals and can efficiently process both hard and soft materials The

View Rollers for Sale in Australia New & Used Machines4u

There are 79 Rollers for sale in Australia from which to choose Overall 76% of Rollers buyers enquire on only used listings, 22% on new and 612% on both new and used Rollers items Buyers usually enquire on 182 different Rollers classifieds before organising finance Vibration increases the soil density and the weight bearing capacity of the

CHAPTER 20: SIZE REDUCTION EQUIPMENT FOR SIZE

– Serrated or toothed roll crusher Smooth roll crusher • Two heavy smooth faced roll rotating towards each other at same speed on parallel horizontal axes • Size of the material caught by the rolls depends upon the coefficient of friction between the material and the roll surface • Dp = 004R + g Dp maximum size of particle R

Construction, Working and Maintenance of Crushers for Crushing

5 Roll Crushers 23 6 Low Speed Sizers 26 7 Horizontal Shaft Impactors 29 8 Ring Granulators 42 9 Rotary Breakers 48 10 Manganese Steel 49 11 For example, a singleroll crusher, employ shear together with impact and compression Shear crushing is normally used under following conditions

Roll Crusher Laboratory Roll Crusher Latest Price,

Find here Roll Crusher, Laboratory Roll Crusher manufacturers, Three Phase Hydraulic Drum Crusher, For Crushing, Capacity: 30 Ton ₹ 3,25,000 Get Latest Price Smooth Double Roll Crusher Usage/Application: Stone,

Roll crusher installation, operation and maintenance

2 Maintenance of the roll crusher (1) Roll crushers require frequent maintenance of the roll surface while in operation (2) Smooth roll crushers are sometimes equipped with grinding wheels on the frame, so that when the roll surface is worn out with pits or grooves, the roll surface can be repaired by grinding on the machine without

McLanahan Double Roll Crushers

The rule of thumb for the Double Roll Crusher’s ratio of reduction is 4:1 The simplified design gives these units excellent reliability and requires very little maintenance The crushers are designed with builtin tramp relief that allows for the passing of uncrushable objects while remaining in continuous operation and returning to the initial product setting

Smooth Roll Crusher JC Steele & Sons

Steele Smooth Roll Crusher —Medium to fine grinding to produce discs, strips or sheets of material The Steele Smooth Roll Crusher plays a key role in bulk raw material preparation, processing clays, coal fines, coke breeze and gypsum waste Twin rollers reduce pebbles and plastic lumps to form thin, flat discs, strips or sheets of material